Filling and sealing products in suitable containers, such as bags, jars, bottles, or pouches.

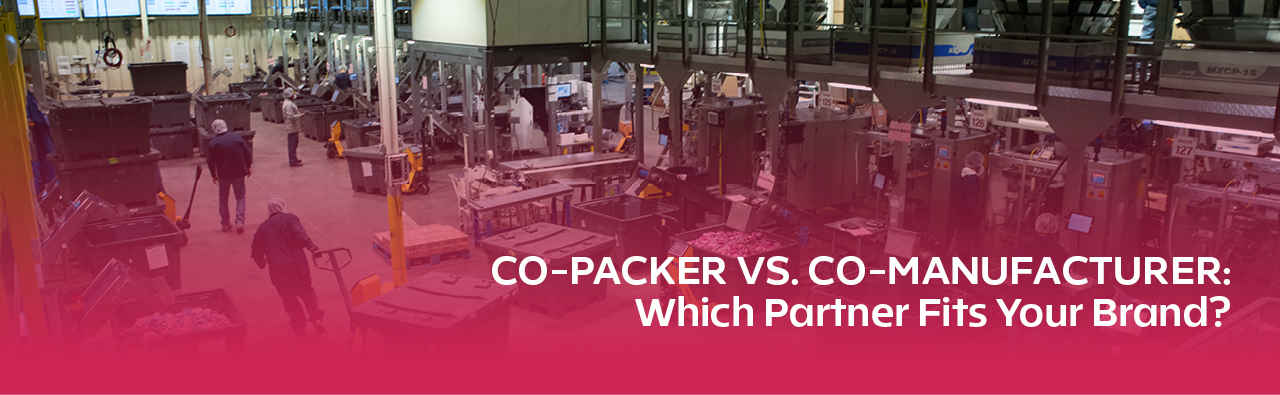

Co-Packer vs. Co-Manufacturer: Which Partner Fits Your Brand?

When a small granola startup secured regional store placement, they suddenly faced much higher production needs. The founder panicked: should they bring in a co-manufacturer to produce more, or rely on a co-packer to handle scaling? Superior Pack Group (SPG), a sweets and snacks co-packer with nearly thirty years of experience, has guided countless brands through this exact dilemma, and here’s what they’ve learned.

Packaging Experts: How Co-Packers Help Brands Grow

A co-packer, or contract packager, focuses on preparing finished products for the marketplace. Their main job is to take a product that a brand has already developed and make it retail-ready. This includes:

Applying labels that meet branding and regulatory requirements.

Portioning to ensure each unit meets exact weight or volume standards.

Specialized packaging such as single-serve packs, multi-packs, and promotional bundles.

Advising on packaging choices that improve efficiency or appeal to consumers, like resealable bags or recyclable materials.

Co-packers work best for brands that already have a finished product. They allow companies to scale distribution without investing in expensive equipment or additional staff. They also provide flexibility, helping brands handle growing orders or new packaging formats while focusing on marketing and sales.

Sometimes, brands need more than packaging support. That’s when a co-manufacturer becomes the right partner.

Co-Manufacturers: Bringing Products from Recipe to Reality

A co-manufacturer, also called a contract manufacturer, handles the full production of a food product. They manage everything from sourcing ingredients to producing and packaging the final product. Their services include:

Recipe development and formulation support.

Ingredient sourcing, including specialty or hard-to-find ingredients.

Quality control at every stage to ensure consistency across batches.

Process optimization to improve efficiency and production flow.

Packaging and labeling that meet branding and regulatory requirements.

Co-manufacturers are ideal for brands that need help creating products from scratch, scaling complex production, or managing multiple ingredients and production steps. They are especially valuable for companies launching new recipes or navigating the challenges of producing consistent, compliant products.

Now that you understand what each partner offers, here’s a side-by-side comparison to help decide which fits your brand.

Packaging or Production: Which Partner Fits Your Brand?

Co-packers and co-manufacturers serve different roles in the food industry, and understanding the distinction is important for any brand. Let’s take a look at how these two partners differ.

Scope of Work

A co-packer focuses on packaging and preparing a finished product for the marketplace. A co-manufacturer manages the entire production process, from sourcing ingredients and producing the product to packaging it for sale.

Control and Responsibility

Co-packers are responsible for consistent packaging, labeling, and compliance with regulations. Co-manufacturers take on broader

responsibilities, including recipe adjustments, ingredient sourcing, and quality control across all stages of production.

When They Make Sense

Co-packers are ideal for brands with established products that need efficient, reliable packaging and distribution. Co-manufacturers are suited for brands that need help developing products, scaling complex production, or managing multiple ingredients and production steps.

Cost Considerations

Because co-manufacturers handle more stages of production, their services typically come at a higher cost. Co-packers usually offer a more cost-effective solution for brands that only need packaging and related services.

Flexibility

Co-packers often provide flexibility in packaging formats and order sizes, allowing brands to adjust quickly to market demand. Co-manufacturers provide flexibility in production processes, recipe development, and ingredient sourcing.

Understanding these differences can help a brand choose the partner that matches its current needs and growth plans. Once you’ve weighed the differences, it helps to clarify your own needs with a few key questions.

Five Questions to Clarify Your Production Needs

Selecting the right production partner begins with understanding your brand’s needs. Ask yourself:

What stage is our product at? Do we already have a finished recipe, or is it still in development?

What volume do we expect to produce in the next year, and can the partner handle it?

What is our budget, and which services are essential versus optional?

How important is flexibility in packaging formats or production schedules?

How will we ensure quality control and meet regulatory requirements?

Answering these questions can help clarify whether a co-packer or co-manufacturer is the best fit. Keeping your priorities in focus ensures the decision is based on your needs, not just cost or reputation.

Are They the Right Fit? Questions to Ask Potential Partners

Once you have a clear sense of your own needs, it is important to assess potential partners carefully. Asking the right questions can reveal whether they are equipped to meet your brand’s goals.

What experience do you have with products similar to ours?

Can you provide references or examples of past clients?

What certifications do you hold, and how do you ensure regulatory compliance?

How do you manage quality control throughout production?

What is your capacity for order volume, and how do you handle fluctuations?

How flexible are you with packaging formats, batch sizes, and production schedules?

The answers to these questions provide insight into a partner’s capabilities, reliability, and fit with your brand. Taking the time to evaluate potential partners thoroughly can help you make a confident decision and avoid surprises later.

The Co-Packer’s Strategic Edge

Going back to the granola startup that we mentioned at the beginning, SPG stepped in to help the brand handle its sudden growth smoothly. The founder had a finished product and large orders, but lacked the in-house capacity to prepare it for stores. SPG’s team guided the brand through every step of getting the product into retailers, applying their deep knowledge of retail requirements and compliance standards.

Packaging is SPG’s core expertise. They handled filling, portioning, and labeling with precision, ensuring each unit met both brand and regulatory expectations. Unlike co-manufacturers, whose focus is on creating and producing the product

itself, SPG concentrated on preparing the granola for the market efficiently and reliably.

With their experience, SPG made what could have been a stressful ramp-up process manageable. The startup could meet demand on time, maintain consistent quality, and avoid costly mistakes. For brands like this granola company, partnering with a co-packer turns a complex logistical challenge into a smooth, predictable operation.

The Right Partner Lets Your Brand Focus on What Matters

Choosing the right production partner depends on your brand’s stage and needs. Co-manufacturers are best for products that require recipe development, ingredient sourcing, or full production support. Co-packers excel at preparing finished products for the market, handling packaging, labeling, and regulatory compliance efficiently.

For brands with an established product, a co-packer can turn growth opportunities into manageable operations, ensuring products reach retailers on time and meet quality standards.

Understanding the differences between co-packers and co-manufacturers helps brands make informed decisions. The right partner lets a brand focus on what it does best—whether creating new products or expanding its presence while leaving production and packaging to the experts.

Since 1995, SPG (Superior Pack Group) has led the co-packing industry with a focus on efficiency, food safety, packaging innovation, and value-added partnerships. Their approach ensures candy and other products reach the shelf quickly without compromising on quality.